Kaizen Cases

Filter Line Changeover Kaizen

— One-Week Intensive Kaizen Event —

1. Background of the Kaizen

In manufacturing operations, changeover is a critical process that directly affects productivity, equipment availability, and operational flexibility. As product variety increases, long changeover times become a major constraint on responsiveness and efficiency.

This Kaizen focused on a filter production line where changeover previously required approximately three hours. By applying the principles of the Toyota Production System (TPS), Lean Manufacturing, and SMED (Single-Minute Exchange of Dies), the team executed a structured, short-term Kaizen to drive meaningful and sustainable improvement in changeover performance.

2. Problem Definition Identified Through Kaizen

Prior to the Kaizen, the changeover process exhibited several structural inefficiencies:

-

Excessive changeover time resulting in extended equipment downtime

-

Significant operator walking and unnecessary motion

-

Tools and jigs located far from the point of use

-

A high number of fasteners increasing manual work content

-

Dependence on individual experience rather than standard work

From a Lean perspective, these issues indicated the presence of Motion, Waiting, and Overprocessing waste, making the process a strong candidate for Kaizen.

3. Kaizen Objective and Approach

The objective of this Kaizen was not simply to work faster, but to achieve process improvement through structural change.

Key Kaizen principles applied included:

-

Shifting from individual effort to process-based improvement

-

Making waste visible through data and direct observation

-

Designing improvements that can be sustained through standard work

All Kaizen activities were completed within a one-week intensive Kaizen event, demonstrating rapid improvement without capital investment.

4. Kaizen Activities and Methods

Optimization of Work Allocation Through Kaizen

During the Kaizen, operators were engaged to support line technicians during changeover, enabling parallel operations instead of sequential work. This change significantly reduced total changeover time and improved teamwork.

Point of Use Storage Introduced by Kaizen

Kaizen analysis revealed excessive walking caused by tool storage locations. Tools and jigs were relocated to the point of use, resulting in immediate improvement in efficiency and ergonomics.

Tooling Simplification Achieved Through Kaizen

The Kaizen team reviewed all tools used during changeover and eliminated unnecessary items. Tool standardization ensured consistent execution and reduced variability between operators.

Fastener Reduction as a Kaizen Outcome

Equipment structure was reviewed during the Kaizen, and unnecessary fastening points were eliminated. This resulted in a major improvement in work content and safety, while also reducing physical strain.

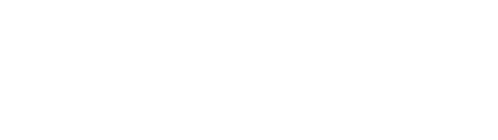

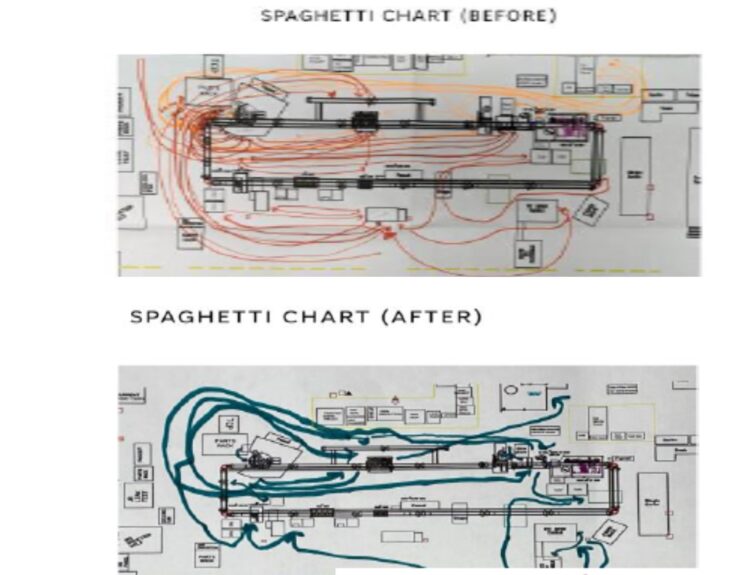

Movement Analysis Using Spaghetti Diagrams in Kaizen

Spaghetti diagrams were created before and after the Kaizen to visualize operator movement. Post-Kaizen diagrams confirmed significant improvement in motion efficiency.

5. Measurable Improvements Achieved

| Metric | Before Kaizen | After Kaizen |

|---|---|---|

| Changeover Time | 2 hr 51 min | 1 hr 25 min |

| Operator Walking Distance | 3,318 ft | 805 ft |

| Jig Transport Distance | 142 ft | 6 ft |

| Number of Fasteners | 102 | 22 |

The Kaizen delivered a greater than 50% improvement in changeover time, directly contributing to higher equipment availability.

6. Implementation Period of the Improvements

While the Kaizen event was conducted over one week, all identified improvements were implemented, tested, and standardized within that same one-week period. Rapid PDCA cycles enabled immediate validation and adjustment.

7. Significance of the Improvements

The outcomes of this Kaizen extended beyond time reduction:

-

Improved equipment availability and OEE

-

Reduced operator workload and enhanced safety

-

Establishment of clear and repeatable standard work

-

Creation of a transferable Kaizen model for other production lines

This case demonstrates how Kaizen as an activity drives improvement as a result, reinforcing Lean culture and supporting long-term operational excellence.