Kaizen Cases

Factory Layout Redesign Kaizen Using 3P (Production Preparation Process)

— Building Just-in-Time Flow Through an Idea Evaluation–Driven Methodology —

1.Background: Why 3P Was Necessary

In many factories, increasing levels of work-in-process (WIP) and long lead times are often regarded as shopfloor operational issues and addressed through partial improvements. However, from the SGC perspective, many of these problems originate from insufficient design during the production preparation stage.

In this case as well, excessive WIP accumulated between processes, transportation distances were long, and Just-in-Time production was difficult to sustain. These issues were not caused by equipment capacity, but by the fundamental fact that the production line had not been designed with flow as a prerequisite.

2.Issues Organized from the 3P Perspective

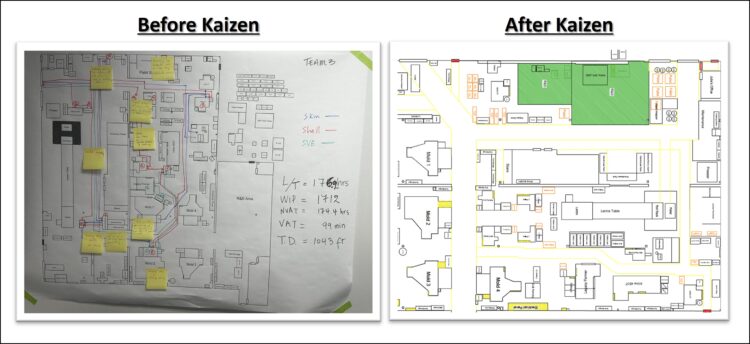

As the first step, current processes were visualized using Value Stream Mapping (VSM) and layout analysis. Issues were then organized from the perspectives of “building quality into the process” and “producing by flow.”

As a result, the following points became clear:

- The process sequence and layout were misaligned, resulting in frequent backtracking and crossing flows

- Excessive inter-process WIP made problems and abnormalities difficult to identify

- Non-Value-Added Time (waiting or stagnation time) accounted for the majority of total lead time

These were structural issues that could not be resolved through improvements to individual processes alone.

3.Definition of 3P (Production Preparation Process) in This Case

In this case, 3P is defined as follows:

3P is a production preparation methodology that starts with idea generation,

develops multiple new production line design concepts,

selects the best design through objective, item-by-item evaluation,

and then deploys it to the actual production line.

This evaluation-based design methodology represents the essence of 3P.

4.Execution of 3P (This Case)

4.1 Idea Generation

Fixed assumptions were eliminated, and Kaizen ideas were freely generated with a focus on processes, layouts, and the movement of people and materials.

(Waste and motion perspectives were actively applied.)

4.2 Development of New Line Design Concepts

The generated ideas were incorporated to create multiple new production line design concepts.

At this stage, emphasis was deliberately placed on not determining a single correct answer, but on developing multiple alternatives in parallel.

4.3 Item-by-Item Evaluation

Each design concept was evaluated both quantitatively and qualitatively using 3P evaluation criteria, including:

- Alignment with takt time

- Feasibility of one-piece flow

- Minimization of WIP

- Minimization of transportation and walking

- Minimum investment with high reusability

- Connectivity to Standard Work

- Assurance of safety and workability

This evaluation itself forms the core of 3P.

4.4 Best Design Selection

Based on the evaluation results, the highest-rated concept was used as the foundation, while superior elements from other concepts were integrated to determine the

Best Design (Best Layout Design).

4.5 Deployment to the Actual Production Line

The selected Best Design was deployed on the shopfloor through a one-week focused Kaizen.

This was not an ad-hoc, idea-driven improvement, but the implementation phase of a design that had been thoroughly validated through 3P.

5.Measurable Improvement Results (Outcomes of 3P)

As a result of the new production line designed and implemented through 3P, the following significant improvement results were achieved:

| Metric | Before | After | Improvement |

| Lead Time | 186 hours | 60.23hours | −68% |

| Waiting Time (NVAT) | 185 hours | 58.5 hours | −68% |

| Work-in-Process Inventory (WIP) | 1,712 units | 391 units | −77% |

| Product Transportation Distance | 948 ft | 178 ft | −81% |

| Available Floor Space | 0 | 1,162 sq. ft | Newly created |

These results were not achieved through simple work improvement, but rather as a consequence of redesigning the production line with flow as the fundamental premise.

6.Implementation Period

This initiative was executed as a one-week focused Kaizen.

Its essence, however, was not a short-term event, but the compressed execution of 3P—designing, evaluating, and making decisions—followed by rapid implementation.

7.Significance of This Case

This case clearly demonstrates that:

- 3P is not a methodology limited to new products or new plants

- It is highly effective for production line redesign in existing factories

- The essence of 3P lies in an evaluation-based design methodology

This methodology can be horizontally deployed to other production lines and plants with a high level of reproducibility.