Kaizen Cases

Simultaneous Reduction of Minor Stoppage and Changeover Losses through Shopfloor-Driven Kaizen

— Downtime Reduction in a Food Manufacturing Production Line —

1. Background

This case study presents a Kaizen initiative conducted on a food manufacturing production line where chronic minor stoppages and changeover losses had been occurring.

Frequent unplanned stops caused by bottle jams, combined with inefficient changeover and material preparation activities, had led to reduced productivity and unstable line operation.

In particular, the causes of minor stoppages had not been sufficiently organized or analyzed on the shopfloor, resulting in reactive, temporary countermeasures. A structured, shopfloor-driven Kaizen approach was therefore required.

2. Issues Identified from SGC’s Professional Improvement Perspective

From SGC’s observation and analysis, the following structural issues were identified:

- Quality checks and changeover tasks were highly dependent on individuals, resulting in workload imbalance and variation

- Standard work was insufficient, making operator training and skill transfer difficult

- Material preparation required a longer lead time than the actual changeover work itself

- Autonomous maintenance for equipment and air systems was weak, allowing minor stoppages to occur repeatedly

These issues indicated the need for an integrated improvement approach addressing work methods, materials, equipment, and operating rules as a whole, rather than isolated countermeasures.

3. Improvement Concept in This Case

The objective of this Kaizen activity was to simultaneously achieve:

- The creation of mechanisms to prevent minor stoppages, and

- Stabilization of changeover and related preparatory work.

Rather than focusing solely on time reduction, emphasis was placed on:

- Identifying root causes and preventing recurrence

- Standardizing and visualizing work

- Building systems that the shopfloor could sustain autonomously

The Kaizen was implemented as a participatory, shopfloor-driven activity.

4. Kaizen Implementation

4.1 Review of Quality Checks and Work Organization

The quality check process was changed from a single-operator task to a three-person operation, distributing workload and improving inspection accuracy.

This reduced the risk of oversight and variability in judgment.

At the same time, standard work sheets were completely revised and restructured together with work standards.

They were visualized using photographs, enabling their direct use for training and on-the-job instruction.

4.2 Analysis and Countermeasures for Minor Stoppages

To address the problem of bottle jams, cause-and-effect diagrams were used to systematically identify contributing factors and root causes.

Through this analysis, it was discovered on the shopfloor that the primary cause was not equipment, but the way materials were fed into the line, including bottle tipping, deformation, and dimensional defects.

To verify this hypothesis, simulations were conducted in which bottles of the correct size were manually fed into the line using the proper feeding method.

These simulations confirmed that minor stoppages did not occur under the correct conditions.

4.3 Improvement of Changeover and External Setup Work

For changeover operations, a dedicated external setup checklist was created to prevent omissions and forgotten tasks.

In addition, a communication board was introduced to continuously collect improvement ideas and needs related to changeover work from the shopfloor, ensuring that operator feedback was visible and actionable.

4.4 Improvement and Standardization of Material Preparation

Analysis revealed that material preparation required more lead time than the actual changeover operation.

The material preparation process was therefore broken down and redesigned to reduce lead time.

To prevent rework during preparation, a material preparation “recipe” was created and standardized.

In parallel, 5S (Sort, Set in order, Shine, Standardize, Sustain) was thoroughly implemented in the material preparation area to improve efficiency and repeatability.

4.5 Strengthening Autonomous Maintenance for Equipment and Air Systems

Since drops in air pressure across the line were identified as a potential cause of minor stoppages, simulations were conducted to replicate minor stoppages caused by air pressure loss.

Based on these findings, the following actions were implemented:

- Repair of air leakage points

- Periodic maintenance of compressors

- Creation of autonomous inspection checklists for equipment

These measures strengthened line-wide autonomous maintenance and reduced the likelihood of recurrence.

5. Quantitative Improvement Results (Improvement)

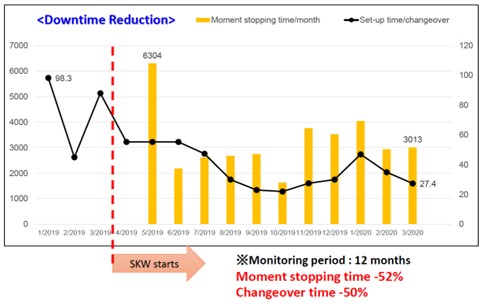

As a result of this series of Kaizen activities, the following quantitative improvements were achieved:

- Minor Stoppage time: 52% reduction

- Changeover time: 50% reduction

The significant reduction in downtime improved line stability and increased the reliability of production planning.

6. Implementation Period

The effectiveness of the improvements was monitored over a 12-month period following the start of Kaizen activities.

A key characteristic of this case is that the improvements were sustained rather than temporary.

7. Significance of This Case

This case demonstrates that even in food manufacturing, integrated Kaizen addressing work methods, materials, equipment, and maintenance can simultaneously reduce minor stoppages and changeover losses.

In particular, the combination of:

- Shopfloor-based fact finding

- Verification through simulation

- Standardization and strengthened autonomous maintenance

provides a highly reproducible improvement model applicable across a wide range of manufacturing industries.