On-Site Kaizen Consulting

Driving Results

from Gemba(On-site)

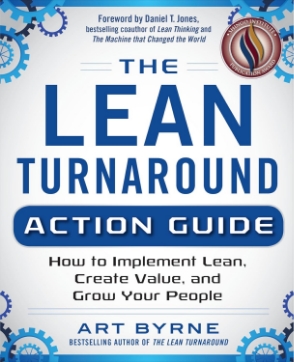

Our consulting doesn’t begin in the conference room—it starts Gemba(on-site), where work actually happens. We follow the “Three Gen” principle: Genchi (actual place), Genbutsu (actual thing), and Genjitsu (actual facts), providing guidance based on what’s truly happening in real time.

Manufacturing sites face a wide range of challenges—safety, quality, productivity, cost, and delivery. Desk-based Kaizen plans or the introduction of advanced tools alone is insufficient for pursuing the true root causes. They tend to result in superficial improvements and do not lead to fundamental problem resolution.

True Kaizen means empowering on-site teams to recognize problems, think critically, and take action. We carry forward the essence of the Toyota Production System (TPS), instilling living Kaizen capabilities tailored to each client’s unique environment.

In many cases, our consulting has delivered returns that exceed the cost of engagement—while embedding a culture of continuous improvement across the organization.

Even in times of rapid change, our mission remains the same: to generate sustainable results from the worksite.

Key Features of the

Shingijutsu Kaizen

Workshop

(SKW)

A Hands-on, Gemba-Based Program That Embeds Kaizen into Daily Operations

Our SKW is a fully immersive, on-site consulting program built on the Gemba principle—improvement begins where the work happens.

Working directly with your team and products, our consultants engage both mind and body to implement and guide Kaizen activities in real time.

Each workshop is customized to reflect your organization’s current conditions and specific challenges. Participants learn the mindset and actions essential for meaningful Kaizen—not just by reading, listening, or observing, but through active, hands-on practice.

The program also includes targeted lectures to deepen understanding of Kaizen culture, helping embed its principles into daily operations and making continuous improvement a natural part of how your organization works.

What Defines Core Kaizen Capability

- The ability to identify Kaizen opportunities related to risk, quality issues, productivity, and waste.

- The ability to generate ideas, implement Kaizens, evaluate outcomes, and achieve goals independently.

- The ability to apply successful initiatives across departments, enabling horizontal deployment.

- The ability to take proactive Kaizen actions without relying on external consultants.

Proven Expertise Across Industries

Proven Expertise Across Industries

Since our founding in 1987, we’ve consistently delivered lean consulting rooted in the Toyota Production System—driving Kaizen at sites around the world, including those of leading global corporations. With operations in 30 countries and more than 300 locations, we’ve provided hands-on Kaizen guidance to over 300,000 individuals worldwide.

In Leading Publications

Our work has been recognized and featured in several influential books on the Toyota Production System, including Lean Thinking, The Machine That Changed the World, and Lean Turnaround.

In addition, our Kaizen initiatives have been introduced and praised in numerous newspapers and industry publications.

Industries

We Have Supported

Transportation Equipment Manufacturers

-

Automotive

(including

components) -

Aerospace

(including parts and

engines) -

Shipbuilding

-

Elevators

Machinery and Equipment Manufacturers

-

Measurement

instruments -

HVAC systems

-

Casting and

foundry -

Motor and

Transformer

Food and Consumer Goods Manufacturers

-

Food products

-

Home

appliances -

Furniture

-

Apparel

Other Sectors

-

Pharmaceuticals

-

Healthcare

institutions -

Insurance

-

Finance

Consultants with Over 20 Years of TPS Experience

Among the many consulting approaches available, the Toyota Production System (TPS) stands apart for its deeply rooted cultural foundation—an approach that cannot be mastered through theory alone. Meaningful Kaizen requires years of hands-on experience.

Our consultants are Kaizen professionals, many with decades of experience at Toyota-affiliated companies or as Kaizen leaders in other organizations—building production systems from the ground up. With over 20 years of direct involvement in TPS, they bring unmatched expertise to every engagement.

We don’t offer surface-level 5S or textbook-style Kaizen. Instead, we deliver practical, customized solutions based on your actual on-site conditions—Kaizen that drives real, measurable results.

Leadership-Driven Oversight

and Guidance

As part of the SKW, we conduct regular on-site audits to evaluate the progress of Kaizen activities.

During these audits, our leadership team joins consultants at the site—not only to review results, but also to provide direct, hands-on guidance and coaching. This active involvement helps ensure that every consultant upholds the highest standards of expertise and instructional quality.

Workflow of the

Shingijutsu Kaizen

Workshop (SKW)

While the SKW follows a basic schedule, its structure and content are always customized to fit each client’s needs, aiming for sustainable cultural transformation.

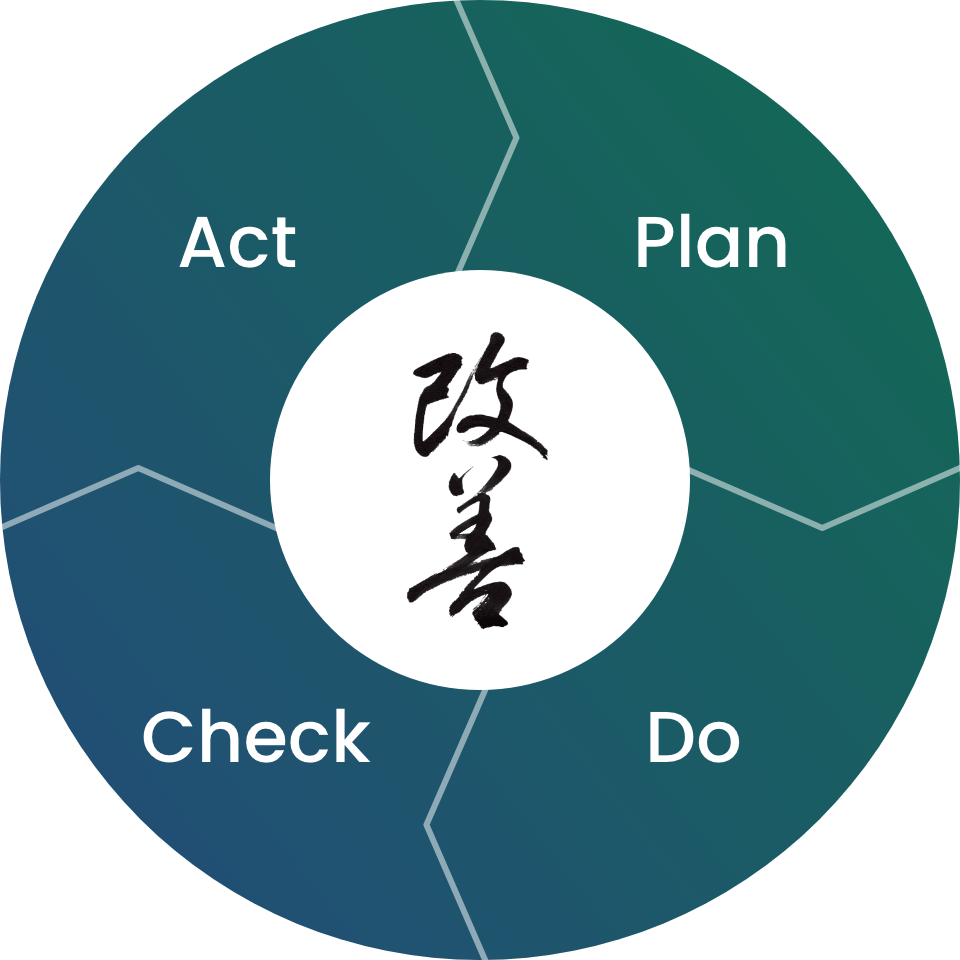

Planning Phase

The Planning Phase is the essential preparation stage before launching the SKW.

Focusing on your representative product, our consultants collaborate with your team to map the production process, clarify organizational objectives, and identify current operational challenges. Based on this analysis, we design and implement targeted Kaizen strategies.

This phase lays the groundwork for a long-term Kaizen roadmap, aligning improvement activities with your strategic goals. It also serves as a foundational learning experience, establishing the standard format for future SKW sessions.

Conducted over five days, the Planning Phase is revisited after the Check and Act stages to refine the roadmap and elevate Kaizen efforts to the next level. The roadmap is continuously adjusted as needed, enabling spiral-up progress. The resulting Plan then becomes the bridge to the next Do phase.

Kaizen Begins Here

This is not a factory audit or a presentation—it’s a hands-on Kaizen initiative carried out within your actual production activities.

It plays a vital role in delivering tangible benefits, such as improved efficiency and reduced costs.

In fact, 88% of our clients report measurable results during the planning phase and choose to move forward with full-scale Kaizen activities.

1. Shingijutsu Kaizen Workshop (SKW)

During this phase, your organization will establish a dedicated Kaizen Promotion Team to lead the workshop. Working closely with our consultants, the team will define specific Kaizen themes and set clear, actionable goals. The workshop is typically delivered in five-day units, enabling focused, hands-on Kaizen activities within a structured one-week cycle.

Core Themes of the SKW

-

Safety

Ensuring a secure and hazard-free work environment

-

Quality

Enhancing product and process reliability

-

Productivity

Maximizing output through efficient operations

-

Cost

Reducing waste and optimizing resource utilization

-

Delivery

Meeting deadlines and improving lead time performance

-

Morale

Fostering motivation and engagement among staff

-

Environment

Promoting sustainability and eco-conscious practices

2. Autonomous Kaizen

During periods without consultant presence, your team enters the Autonomous Kaizen phase.

In this stage, your team independently tackles the challenges identified in the previous workshop—working toward resolution before the next session. By repeating this cycle of solving current issues and preparing for new ones, you steadily advance toward your long-term Kaizen goals.

A key aspect of this phase is sustaining and managing improvements. Even the most effective changes can fade without consistent oversight and strong commitment from leadership.

By establishing autonomous Kaizen periods, we aim to embed self-directed Kaizen practices and cultivate lasting organizational independence.

Audit

We regularly assess the progress and achievement level of Kaizen activities.

This includes verifying the current implementation status and identifying any unmet goals. When targets are missed, we investigate the root causes and take corrective action to ensure continuous improvement.

Adjustment and Refinement

Based on audit findings, we adjust the direction, objectives, and schedule of Kaizen activities as needed. If company policies change, we revise the Kaizen plan accordingly to maintain strategic alignment and ensure continued progress.

Speaking Up to

Leadership Is Part of

Our Role

Some issues uncovered on the shop floor cannot be resolved at the operational level alone—especially when they originate from upstream factors such as company policies or strategic directives.

In these cases, our consultants take the initiative to escalate concerns to senior management, advocating for structural changes that support sustainable Kaizen.

By bridging the gap between frontline realities and executive decision-making, we help ensure that Kaizen efforts are not only effective, but also backed by organizational commitment.

Consulting

Case Study

Manufacturing

– Aerospace Industry

Initial Conditions & Challenges

Long lead times, poor process visibility, batch production hiding abnormalities

Actions & Results

The client faced long lead times and limited visibility across the production line. Batch-based operations made it difficult to detect abnormalities in real time. To resolve these issues, we restructured the production system—cutting lead time by half and introducing continuous flow aligned with takt time. We also implemented one-piece flow, enabling immediate line stoppage when abnormalities occur. This approach improved efficiency and stabilized product quality.

General Hospital

Initial Conditions & Challenges

Long lead time from reservation to testing, lengthy room cleaning times

Actions & Results

The hospital faced long lead times and excessive time spent on cleaning tasks.

To address this, we identified root causes and sources of waste. Key measures included:

- Point-of-use placement for supplies

- Post-use replenishment of consumables

- Standardization of formats such as prescriptions used by doctors and nurses

We also introduced standardized triage protocols in emergency care and optimized inventory management through proper stock levels and strict first-in, first-out practices. These initiatives significantly reduced lead time and greatly improved operational efficiency across the hospital.