Safety

By consistently following rules for attire, protective equipment, and Work Standards, accidents and injuries are reduced.

Kaizen is a Japanese word that means “improvement”. It’s about making “change” for the “better”-step by step, every day. The word and idea of Kaizen became known around the world when Toyota expanded its factories overseas and shared its improvement methods based on the Toyota Production System (TPS). Kaizen, a concept rooted in Japanese philosophy, is recognized as a method of continuous improvement through small, incremental changes to processes, products, or practices.

Originally developed for manufacturing, Kaizen has since been adopted across a wide range of industries—including IT, finance, and healthcare. Regardless of time, place, or organizational size, Kaizen remains a powerful and adaptable methodology for driving sustainable change.

Kaizen delivers a wide range of benefits, from enhancing customer satisfaction and corporate value to improving workplace safety and morale.

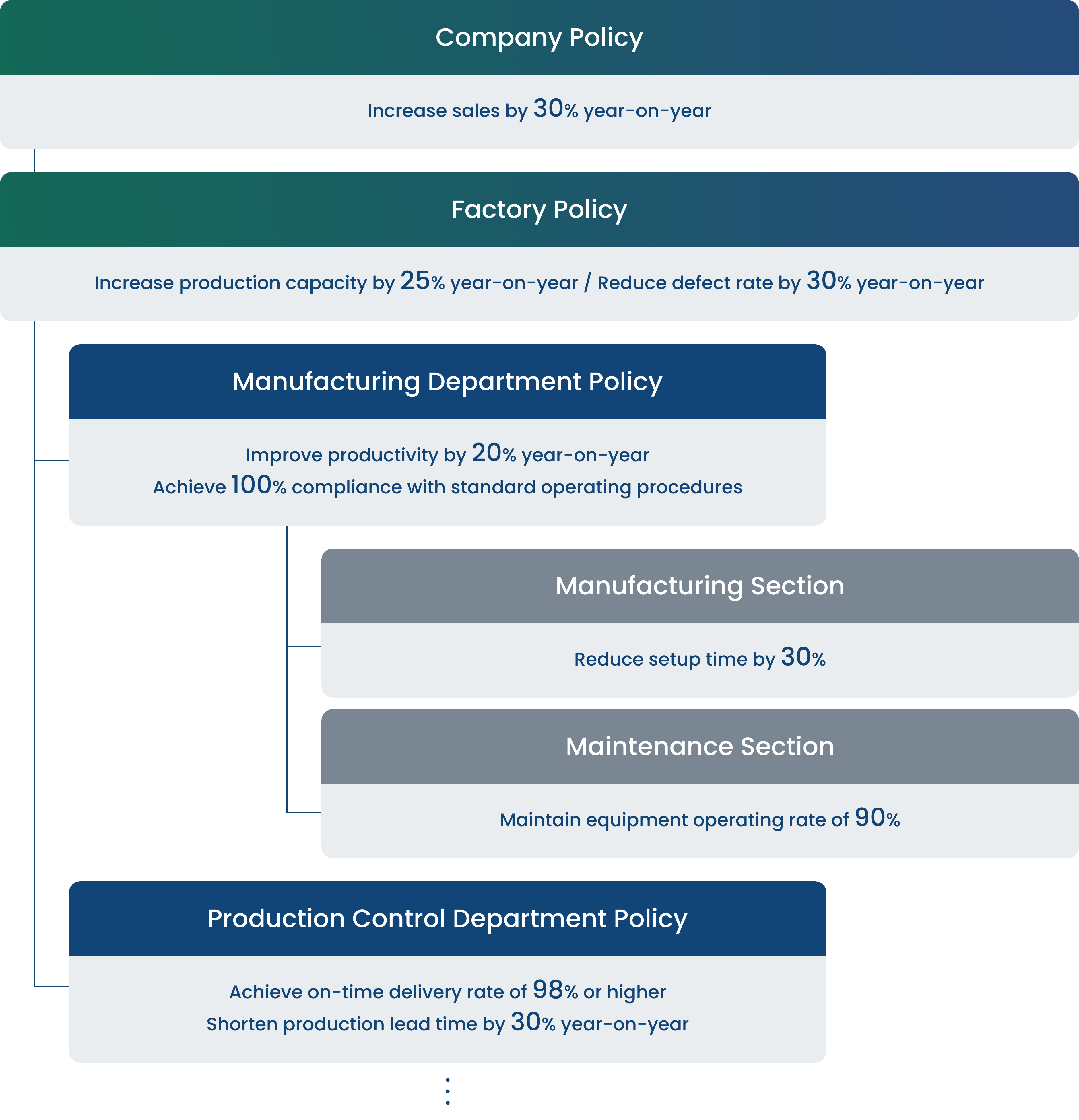

To meaningfully improve quality, productivity, delivery, and cost, it is important to align management from both strategic (Policy Management) and operational (Daily Management) perspectives, working in both top-down and bottom-up directions.

Policy Management enables senior leadership to deploy mid- to long-term goals and key priorities across the organization, fostering alignment toward a shared direction. Daily Management helps frontline teams stabilize operations, identify problems early, suggest Kaizen ideas, and strengthen Standard Work to prevent issues from recurring.

When strategic guidance from management connects with creativity and initiative from frontline, organizations achieve lasting results and continuous improvement.

Kaizen at the operational level is valuable—but not enough to drive major change across the organization. To reach strategic goals like profit growth, Kaizen efforts must follow a clear and consistent framework—from company-wide and departmental policies to individual targets. By applying the PDCA cycle to these shared goals, organizations can realize efficient, goal-oriented growth.

Daily management refers to activities that ensure stable and efficient operations based on established standards and criteria, with the aim of maintaining and improving target performance levels. On the worksite, members regularly track key indicators like output, quality, defect rates, and equipment usage. This helps them spot abnormality and problems early and take quick action to fix them. By collecting Kaizen ideas directly from the worksite—and connecting them to standardization and prevention—organizations can maintain stable operations while continuing to improve.

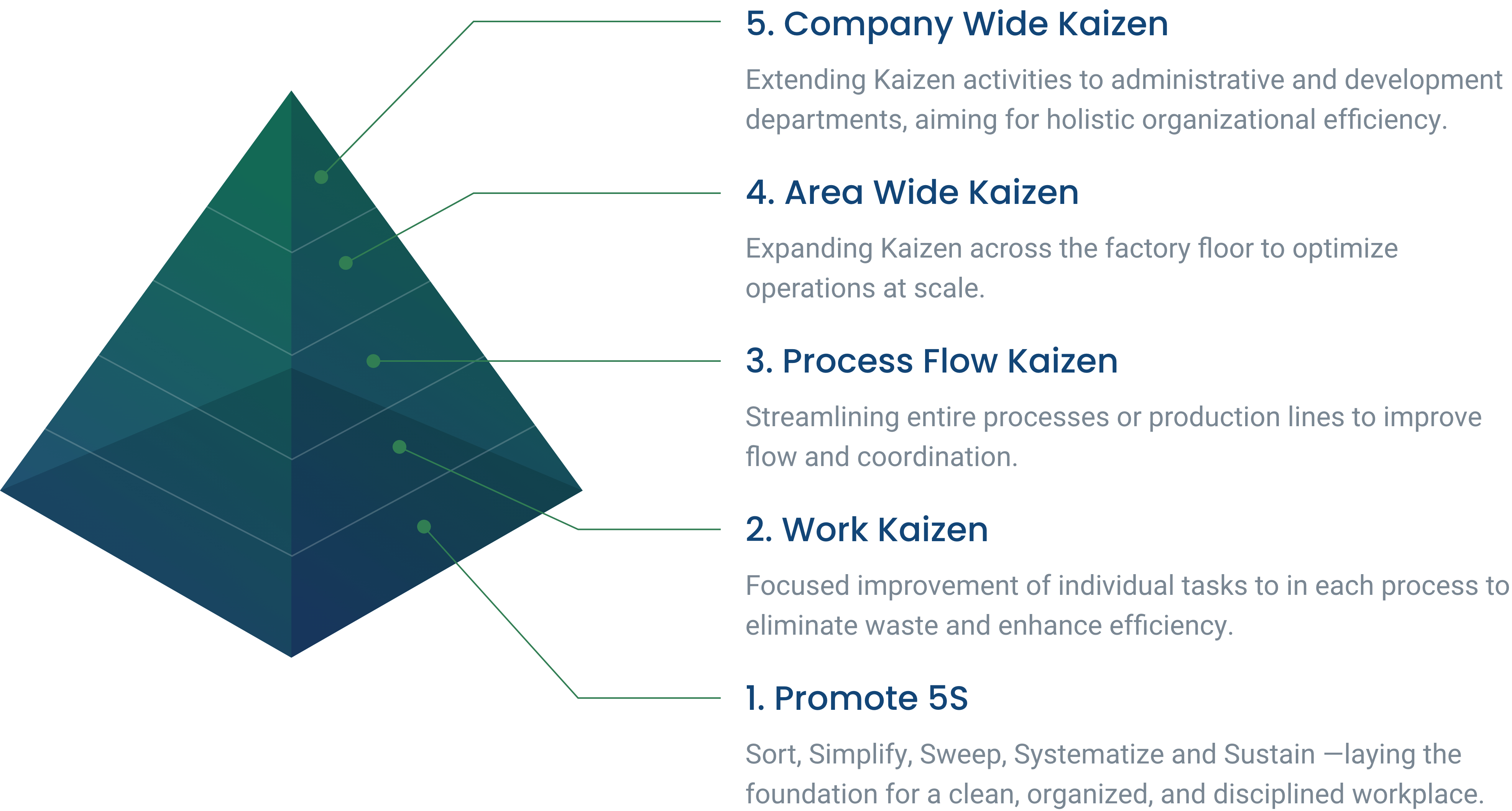

For companies new to Kaizen, a phased approach is most effective.

It starts with 5S activities to organize the workplace and create a strong foundation for improvement. Next, process-level work improvements are implemented to eliminate waste and standardize operations, followed by line-level optimization that connects individual processes for greater efficiency. From there, efforts expand to broader areas across the factory, and eventually to company-wide deployment, including administration and R&D departments. By moving through these steps, organizations build lasting results and strengthen their overall competitiveness.

To build a culture of Kaizen, it’s essential to develop people who can put Kaizen into action—not just understand it in theory. At Shingijutsu Global Consulting, we offer on-the-job training (OJT) that helps employees absorb the mindset and habits needed for Kaizen through hands-on experience in the workplace.

Our approach to OJT (on-the-job training) goes beyond teaching technical skills. We focus on developing people who can think for themselves and take action to improve. By instilling key principles of the Toyota Production System—such as Standard Work and Genchi (actual site) / Genbutsu (actual thing)—we help employees not only improve their own tasks, but also support and guide others in doing the same.

Teaching

Standard Work

We help employees create clear rules that ensure consistent results—no matter who performs the task. When something deviates from the standard, they learn to analyze the cause, make improvements, and update the standard accordingly.

Teaching Genchi Genbutsu (Go and See)

When problems occur, we promote direct observation of the actual site, product, and equipment—rather than relying on assumptions—to uncover the real root cause.

Teaching

the Kaizen Mindset

Instead of simply memorizing tasks, we encourage employees to ask: “Why is this step necessary?” and “What waste can be removed?” This builds deeper understanding and a sense of ownership.

Shingijutsu Kaizen Workshop (SKW)

We offer “SKW” to help embed a culture of improvement directly at the worksite. Our consultants—each with over 20 years of hands-on experience in the Toyota Production System—visit client facilities to cultivate site-based Kaizen expertise tailored to each organization’s unique needs.

Practical Kaizen Training

We regularly host Practical Kaizen Training programs in Japan, designed to teach the principles of the Toyota Production System through direct experience. Over five days, participants actively engage both mind and body—practicing Kaizen through the simulation and steadily building a clear understanding of its core methods and philosophy.