News &

Column

2025 Practical Kaizen Training Successfully Conducted

Dates: Monday, September 8 – Friday, September 12, 2025

This program was designed to strengthen participants’ ability to implement improvements directly on the shop floor by combining classroom learning with hands-on exercises.

Day 1 | First Step in Improvement — Understanding the Basics of Kaizen

The program kicked off with an introduction to the fundamental concepts and objectives of Kaizen.

The program kicked off with an introduction to the fundamental concepts and objectives of Kaizen.

Through group discussions and interactive activities, participants actively exchanged ideas, creating a highly energetic and engaging start.

The first day set a strong foundation and built momentum for the five days of continuous improvement ahead.

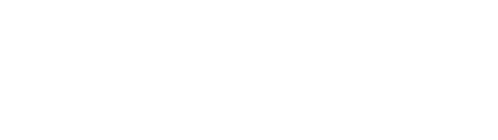

Day 2 | Problem-Solving Using the QC Story

Day 2 focused on structured problem-solving using the QC Story methodology.

Day 2 focused on structured problem-solving using the QC Story methodology.

In a dart game exercise, participants practiced QC Circle activities by collecting data, analyzing root causes, and developing improvement ideas.

The exercise was both enjoyable and serious, allowing participants to experience how systematic problem-solving can be effectively applied in the workplace.

![]()

![]()

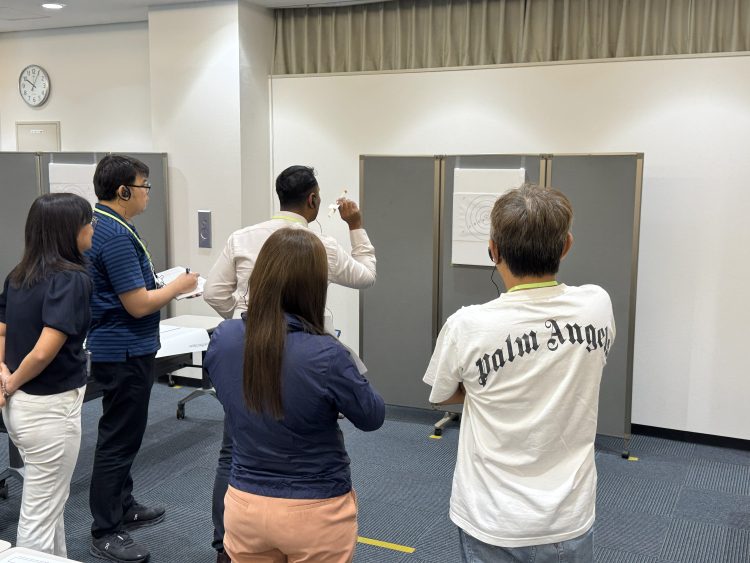

Day 3 | Learning the Kanban System Through Hands-On Practice

On Day 3, the training centered on the Kanban system.

On Day 3, the training centered on the Kanban system.

After a classroom session covering its structure, purpose, and roles, participants moved on to a hands-on workshop using mock production lines.

They experienced the flow of production and withdrawal Kanban cards while picking parts, assembling products, and delivering finished goods to the “customer.”

This practical simulation deepened their understanding of how Kanban works in real operational settings.

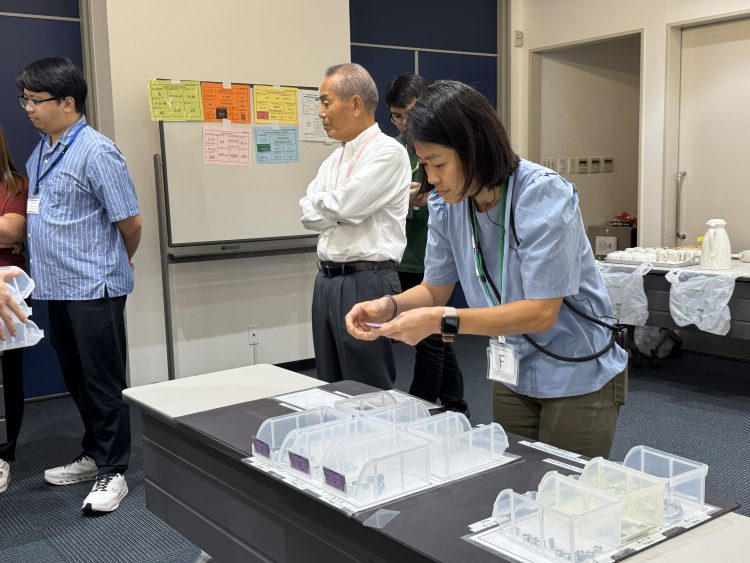

Days 3–5 | JIT and 3P-Based Production Innovation Simulation

During the final two days, participants tackled a comprehensive assignment focused on Just-In-Time (JIT) production.

During the final two days, participants tackled a comprehensive assignment focused on Just-In-Time (JIT) production.

Working in two cross-functional teams, they progressed through three phases:

-

Experiencing batch production

-

Transitioning to one-piece flow

-

Designing and simulating a new production line using the 3P (Production Preparation Process) approach

Together, the teams pursued goals such as achieving required production volume, reducing manufacturing costs, increasing profitability, and enhancing customer satisfaction.

The results of their improvements were verified in a tangible and measurable way.

To conclude the program, a certification ceremony was held to recognize the participants’ efforts, marking the completion of a rewarding five-day learning experience.

“Improvement is never a solo endeavor.

It requires shared thinking, experimentation, validation, and continuous evolution with your teammates.”

This insight strongly resonated with everyone involved in the training.

Participant Feedback

The Practical Kaizen Training held in September received extremely positive feedback.

In post-training surveys, 100% of participants rated the program as “satisfied.”

Key highlights included:

-

Realistic, shop-floor-based exercises

“Simulations based on actual shop floor scenarios were extremely helpful.” -

Turning Kaizen ideas into action

“Both successes and failures became valuable learning opportunities, clarifying how to move improvements forward.”

SGC remains committed to supporting sustainable growth by developing professionals who can drive Gemba Kaizen through practical, hands-on learning.