News &

Column

News

Events

2025.12.24

Upcoming Practical Kaizen Training – June 2026

Dates: Monday, June 1 – Friday, June 5, 2026 (5 Days)

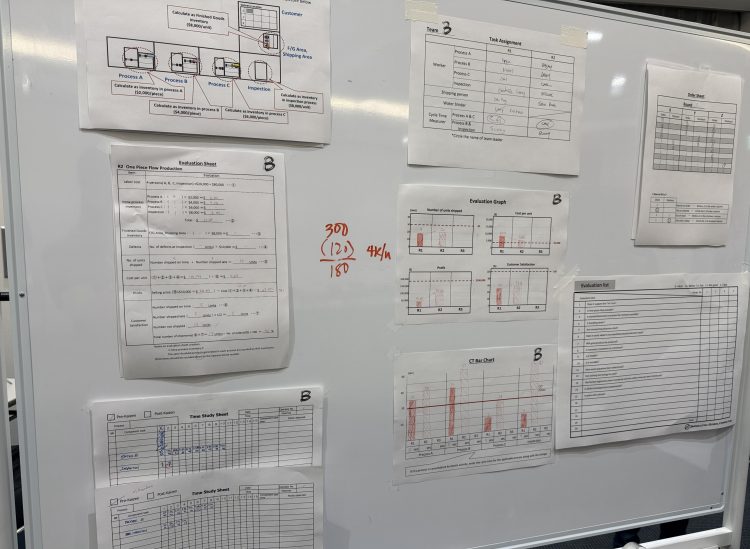

This five-day program is designed to help participants learn both the fundamentals and practical application of Kaizen, based on the Toyota Production System.

Through a combination of lectures and hands-on simulations, participants will gain skills that can be immediately applied on the shop floor.

The training is suitable not only for manufacturing professionals, but also for those in non-manufacturing industries.

Purpose of the Training

Kaizen delivers true value only when people clearly understand why improvement is necessary, what should be improved, and how to continuously implement improvement at the Gemba.

This program aims to:

- Build a solid understanding of Kaizen principles and philosophy

- Equip participants with practical methods, steps, and techniques for on-site improvement

- Provide perspectives on how to establish Kaizen as a sustainable organizational culture, rather than a one-time activity

Key Training Topics

(Lectures and Practical Simulations)

- Kaizen Fundamentals and Standard Work

- What Kaizen is and why improvement is essential

- Understanding waste (Muda), 5S, and the importance of standardization

- Learning Kaizen procedures through hands-on simulation exercises

- Problem Solving Using QC Methods

- Understanding and analyzing the current state accurately

- Root cause analysis using QC tools

- Structured problem-solving practice through the QC Story approach

- Material and Information Flow (Value Stream Mapping)

- Visualizing problems by correctly capturing the current state

- Creating and using Material & Information Flow Charts (Value Stream Maps)

- Identifying why improvement efforts often fail when this step is overlooked

- Just-In-Time (JIT) and the Kanban System

- Experiencing the differences between batch production and JIT production

- Understanding pull systems and Kanban-based production

- Visualizing waste in production and logistics through simulation

- 3P (Production Preparation Process)

- Applying 3P in new product launches, new lines, and process or equipment changes

- Designing processes that achieve high quality, high productivity, and profitability

- Learning and practicing 3P through production line design simulations

- Establishing a Kaizen Culture

- Why Kaizen often fails to take root within organizations

- The role of management in sustaining Kaizen

- What is required to embed continuous improvement into daily operations

Who Should Attend

- Individuals who want to learn how to improve operations systematically

- Managers and leaders responsible for operational performance

- Kaizen promotion leaders and continuous improvement practitioners

- Internal Kaizen trainers and specialists

- Anyone committed to practicing and sustaining Kaizen