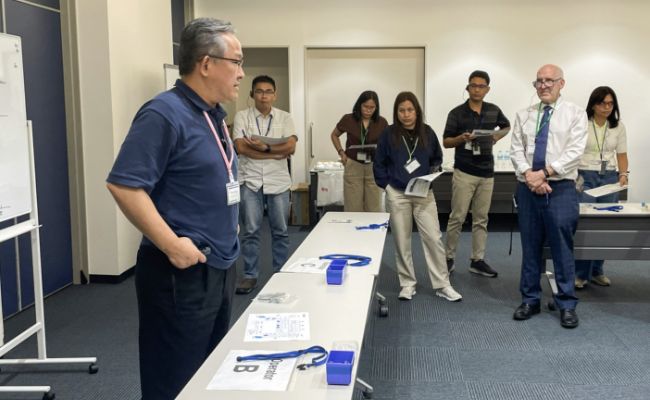

Deepening Your Understanding of Kaizen

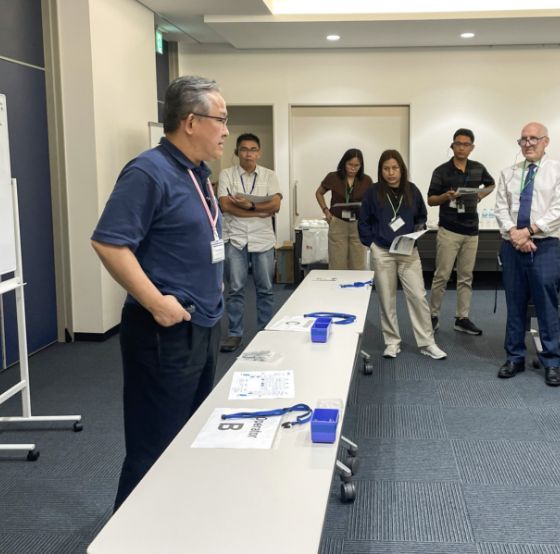

Why does your workplace need Kaizen?

Kaizen without clear purpose—adopted as a formality—has little value. The first step is to define the objective. Through thoughtful inquiry into questions such as “What should be improved on-site?”, “What is Muda (waste)?”, and “Why do we practice 5S?”, participants explore the essence of Kaizen and develop a mindset rooted in purpose.