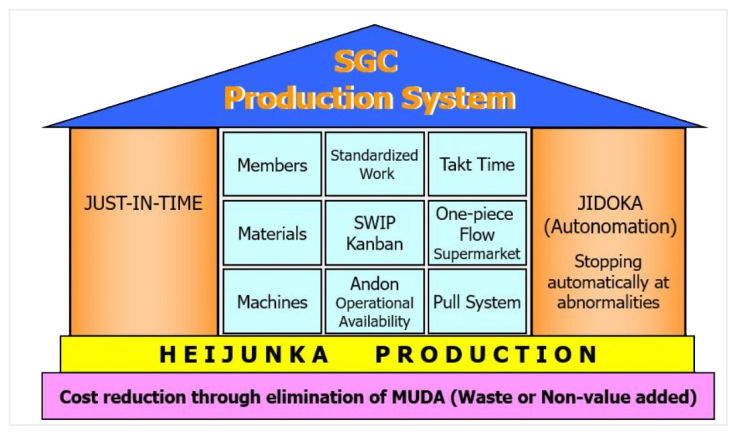

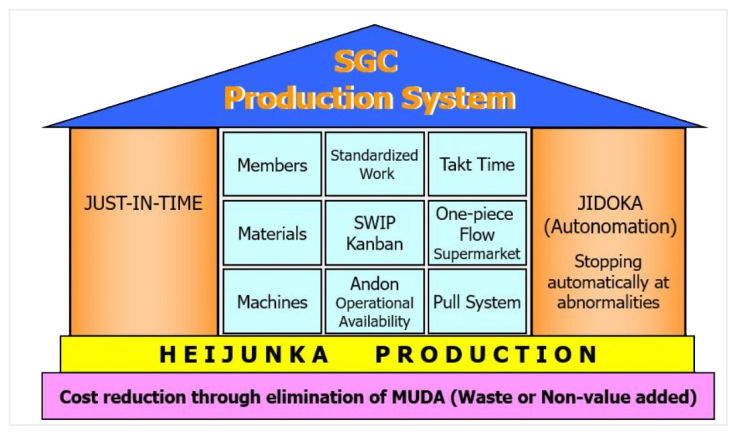

Shingijutsu Global Consulting is a specialized consulting firm focusing on improving the efficiency of manufacturing, logistical systems, and other business operations (known as Kaizen, Lean operation or Continuous improvement). Shingijutsu Global Consulting effectively combines a client's people, materials, facilities, and information through a concept we call the Shingijutsu Global Consulting Production System (SGC-PS). The SGC-PS is Shingijutsu Global Consulting's Kaizen technology based on the Just-In-Time (JIT) methodology originally developed by Toyota (well-known as the Kanban system).

To remain competitive in the world marketplace, it is imperative that a company be able to respond quickly to various market demands, such as short Lead times, greater variety of products in lower quantities, price pressure, etc. Shingijutsu Global Consulting first assists clients in identifying areas for improvement in all aspects of their business, then leads them through the process of implementing our methods to achieve their efficiency goals. Our clients receive the full benefit of our combined expertise and experience in Kaizen technology, developed and accumulated through long-term relationships with world-class manufacturing companies such as Boeing, Porsche, and Pratt & Whitney.

Shingijutsu Global Consulting's creates a unique lean production system tailored to each client's specific requirements, always based on the SGC-PS. The goal is to enable clients to identify their problem areas, develop strategies to improve them, and to education and train their employees in the practice of Kaizen in the workplace. We support the manufacturing, logistics, and service industries through on-site consultation and seminars.

Shingijutsu Global Consulting's consultants work with the client's staff to continuously assess and restructure the company's operational systems to improve efficiency and profitability. Since the company's employees are an integral part of the improvement process, Shingijutsu Global Consulting expects the client to return 30% of the profits it gains through implementing Kaizen to its employees.

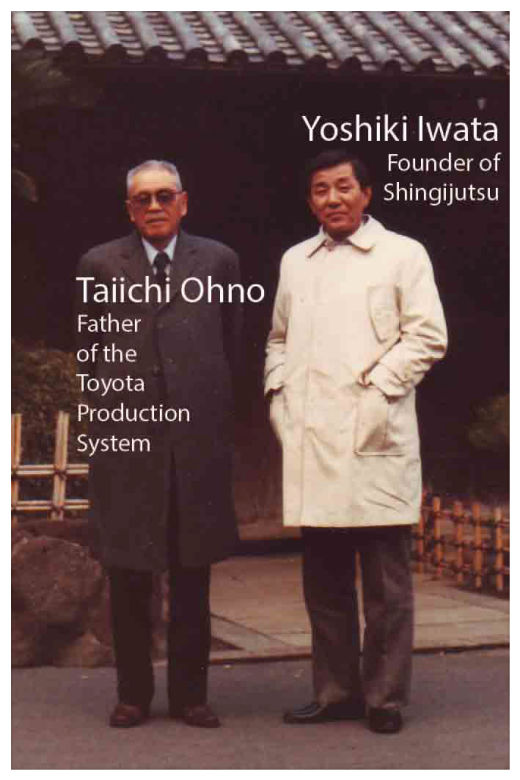

In 1987, Shingijutsu was formed in Nagoya, Japan. The founder, Yoshiki Iwata, was an original member of the Toyota Autonomous Study Group (a project team comprised of Toyota's suppliers). This Study Group first developed Toyota's lean production practices (the Kaizen system).

The study activities enabled Mr. Iwata to contribute in establishing the Toyota Production System (TPS) as a primary pupil of Mr. Taiichi Ohno (an originator of the TPS concept). After his long career as a Toyoda Gosei plant manager, Mr. Iwata founded Shingijutsu in order to promote this Kaizen system throughout the world. Despite being a start-up company, Shingijutsu was soon engaged to provide consulting by such world-class companies as Yamatake Corp (Azbil)., Isuzu Motor Ltd., and Showa Manufacturing Co., Ltd. Shingijutsu brought the Kaizen system to a wide range of industries, including automotive, electronics, and printing. Shingijutsu provided consulting to about 160 clients worldwide at more than 600 sites, from manufacturing sites to logistics and service industries, such as maintenance, security, consulting companies, and hospitals.

In January 1996, The New York Times published a full two-page article describing Mr. Iwata's contribution to the rehabilitation of the German sports car manufacturer, Porsche. Porsche had asked Shingijutsu for consulting services after the company lost 240 million Marks in July 1993. Porsche's product line-up hinders straight production because the company produces few units of many different models of cars. The beneficial effects of the Kaizen were quickly and dramatically apparent: daily production increased from 40 to 80 vehicles. In 1995, Porsche successfully returned to profitability by implementing the Kaizen methodology that Shingijutsu had proposed.

Yoshiki Iwata passed away in 2001, and differing visions of the future of Shingijutsu in 2003 and about its marketing strategy arose within Shingijutsu. At that time, Mr. Iwata's daughter, Kumi Iwata Otake, along with Senji Niwa, Takeshi Iwata and other senior consultants, decided to form a new company, Shingijutsu Global Consulting Co., in order to preserve and develop Yoshiki Iwata's original business concept.

In 2004, SGC opened a U.S. subsidiary called Shingijutsu Global Consulting in Bellevue, WA to better serve clients and expand Kaizen consultation services to the companies all over the world.

Mr. Iwata joined Shingijutsu in 1999, and founded Shingijutsu Global Consulting in 2003. He is skilled in adapting TPS concepts to clients who are not in the manufacturing industry. He has a reputation for his easy to understand teaching methods and he has established his credibility by getting exceptional results with his clients. Recently his reputation as an effective Kaizen consultant has been well recognized, especially in the healthcare industry. Prior to working for Shingijutsu, Mr. Iwata engaged in promotion of the Kanban system in the production and distribution departments at Rinnai Corp. His expertise is in the areas of materials and information flow.

Ms. Iwata-Otake joined Shingijutsu in 1987, at the formation of the company, as a Chief Financial Officer and Director. She was in charge of the company's general affairs, assisting Mr. Iwata, founder of Shingijutsu, her father. Since 2002, she has contributed to establishing solid relationships with U.S. clients, including Boeing. As a result, many U.S. clients admire and trust her business sense and policies. She currently is Chairwoman of Shingijutsu Global Consulting based mainly in Washington State. Prior to working for Shingijutsu, Ms. Iwata-Otake worked for Toyota Tsusho, and was in charge of exporting spinning machinery mainly to Asian markets.

Shingijutsu Global Consulting has a variety of Japan-based consultants; all of whom have decades of Kaizen experience at Toyota Group companies, etc. For more information on the consultants best suited to your industry, please contact an Shingijutsu Global Consulting representative.

1956 - 1989

Toyota Boshoku

1989 -

Present Shingijutsu

1962 - 1993

Isuzu Motors

1993 -

Present Shingijutsu

1964 - 2007

Toyota Auto Body

2007 -

Present Shingijutsu

1969 - 1999

Isuzu Motors

1999 - 2008

Isuzu Techno

2008 -

Present Shingijutsu

1968 - 2005

Toyota Boshoku

2005 - 2009

TB Service

2009 -

Present Shingijutsu

1969 - 2016

Toyota Auto Body

2017 -

Present Shingijutsu

1970 - 1995 Denso

1995 - 1999 TBDN ,USA

1999 - 2012

Toyota Boshoku

2015 -

Present Shingijutsu

1971 - 2000

Toyota Auto Body

2000 - 2011

Asahi University

2011 - 2017

Chubu Gakuin UV.

2017 -

Present Shingijutsu

1980 - 2013

Toyota Boshoku

1984 - 1985 Denso

1992 - 1994

Toyota Motors

2013 - 2017

TB Malaysia

2018 -

Present Shingijutsu

1976 - 2019

Toyota Boshoku

2002 - 2006

TBFST

2008 - 2012

Kyoei Araco

2019 -

Present Shingijutsu

1965 - 2010

Otics

2011 - 2019

Kaizen Consultant

2019 -

Present Shingijutsu

1980 - 1986

Nippon Trail mobile

1986 - 1990

Misawa Homes

1990-2019

Toyota Auto Body

2019-

Present Shingijutsu

1980 - 2017

Toyota Auto Body

2018 - 2021

Ace Industry

2021 -

Present Shingijutsu

1975 - 2019

Toyota Auto Body

2022 -

Present Shingijutsu

1970 - 2009KYB

2010 - 2011 SANY

2011 - 2014 Zoomlion

2015 - 2022

Onda MFG

2022 -

Present Shingijutsu

1970 - 2011

Tokai Rika

2011 - 2023

Kaizen Consultant

2023 -

Present Shingijutsu

1981-2023

Toyota Boshoku

2007-2012

TB Shiga

2012-2022

Toyota Boshoku Mississippi

2024-

Present Shingijutsu