Where there is no Standard, there can be no Kaizen

-Taiichi Ohno

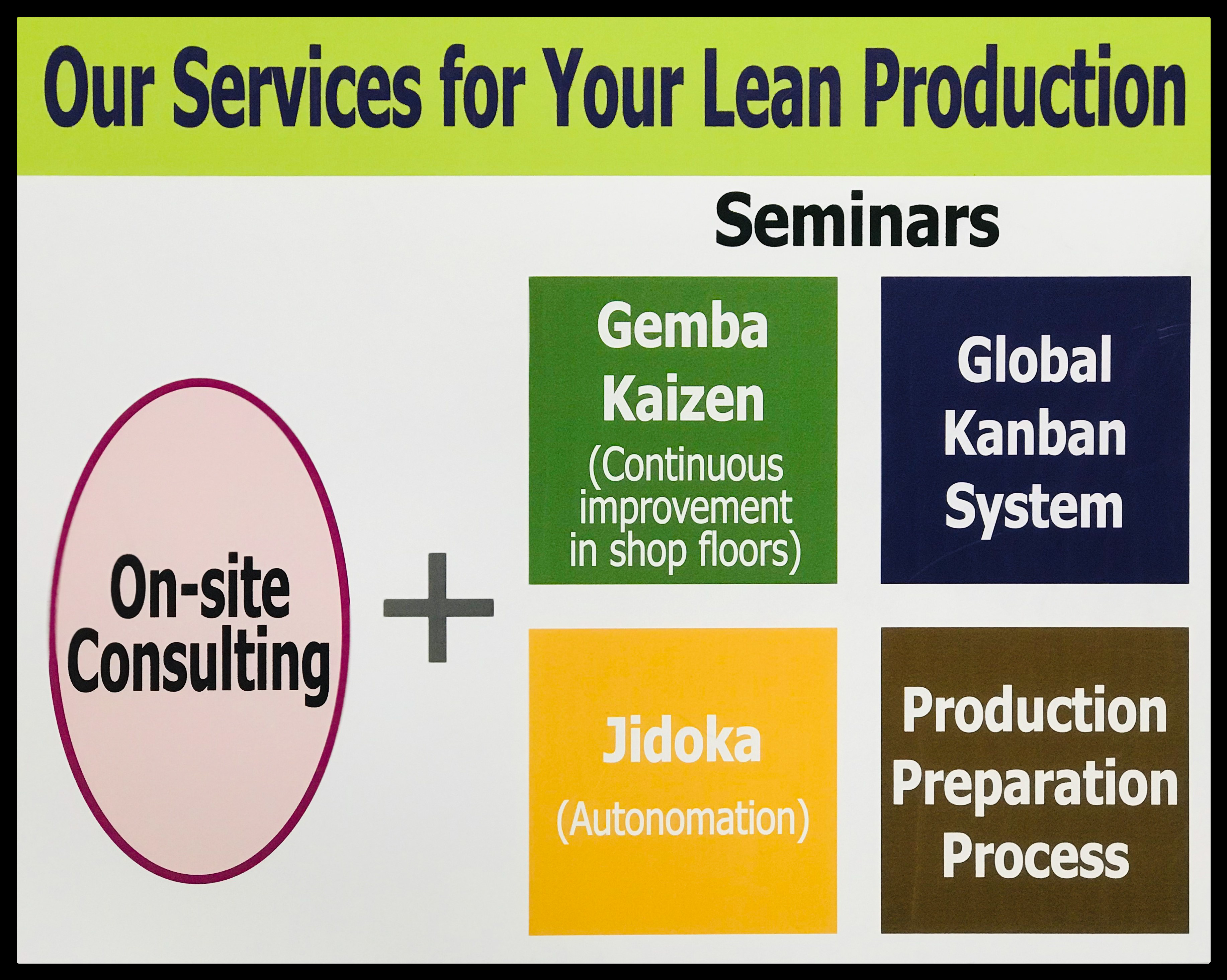

It's no secret that effective management enhances customer satisfaction and increases profits. Every business, regardless of its size, product, or corporate history, strives for high production at low cost, streamlined logistics, and efficient operations. However, while the goal is clear (reducing wasteful inefficiency), companies often lack the necessary tools to identify productivity problems and develop effective and lasting solutions. Shingijutsu Global Consulting specializes in helping companies achieve Lean production through Kaizen (Continuous improvement) using several proven methodologies such as Just-In-Time (JIT), Heijunka (leveled production), Jidoka(autonomation).

The Kaizen system, pioneered by Toyota in Japan, has been recognized as the premier efficiency technology in the business world, reducing unrecognized Muda (waste) in production and management practices, in some instances by as much as fifty percent. Many large manufacturing companies, such as Boeing, have used our consulting services and seminars to achieve more effective and efficient operations.

SKW (Shingijutsu Kaizen Workshop)

Gemba Kaizen

Logistics Kaizen

3P . . . and more!

The core approach to implementing Kaizen at your Gemba

Japan Tours

US Events

Private Program

An introduction to Lean

(Toyota Production System)

and Essential Kaizen Concepts

Know-how : SGC has the knowledge and tools to help your company improve profit and customer satisfaction through Lean practices...

Education : Our consultants' teach from Gemba and train your team through a hands-on approach to Kaizen...

Get started : Contact an SGC representative to start your Kaizen journey to Lean practices...Contact Us!

Kaizen Lean Revival &

Problem Solving

TBD

2015 Learn True Lean from KAIZEN Pioneer - Annually each autumn

THE TOYOTA PRODUCTION SYSTEM IN NORTH AMERICA, This past November I was invited to give a presentation on my book, THE LEAN TURNAROUND, at a Lean seminar hosted by Shingijutsu Global Consulting in Jackson, TN.

This was a working seminar that included a couple of very impressive plant tours of the North American plants of one of Toyota's subsidiary companies. The participants were very enthusiastic about what they heard and saw during the seminar and as a result it was a pleasure to talk with them and answer all their questions. As a long time practitioner of the Toyota Production System and Lean it was nice to see that, with the help of experts like Shingijutsu, Lean is alive, well and growing in the US.

The First Kaizen Promotion Office Director of Boeing

Without Shingijutsu’s consulting, Boeing would have never been able to roll out the 10,000th 737. I know because I was there. I was instrumental in getting 1700 Boeing managers to Japan to attend Shingijutsu training and the results have put Boeing at the forefront of commercial airplane production in the world. Shingijutsu was key in putting in place a moving assembly line initiated in 1997. Boeing Managers’ trips to Japan to study the Toyota Production System and the technical advice of our Shingijutsu Sensei’s and made it all happen.

John Black - John Black & Associates(JBA)

Upon retiring, Mr. Black formed JBA and began helping other organizations successfully and profitably apply the Toyota Production System (TPS) model-often called “Lean production” or just “Lean”ーto their own operations. While still at Boeing, however, Mr.Black spoke at a 1995 quality conference attended by the CEO of PeaceHealth. That healthcare organization subsequently embarked on the Lean journeyーlong before Lean became a topic in healthcare—led by Ms. Joanne Poggetti of Poggetti and Associates (and Mr. Black’s former Boeing colleague). Mr. Black provided support, and early results were astounding.