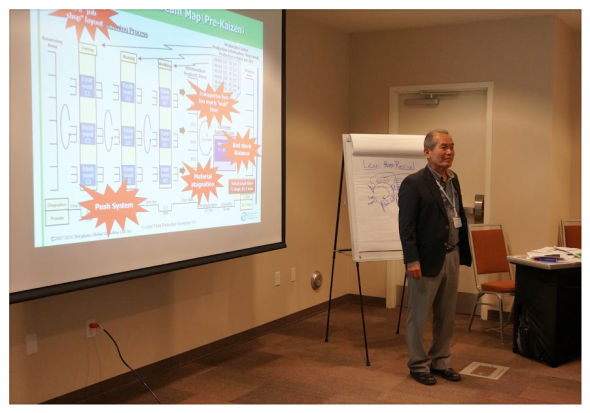

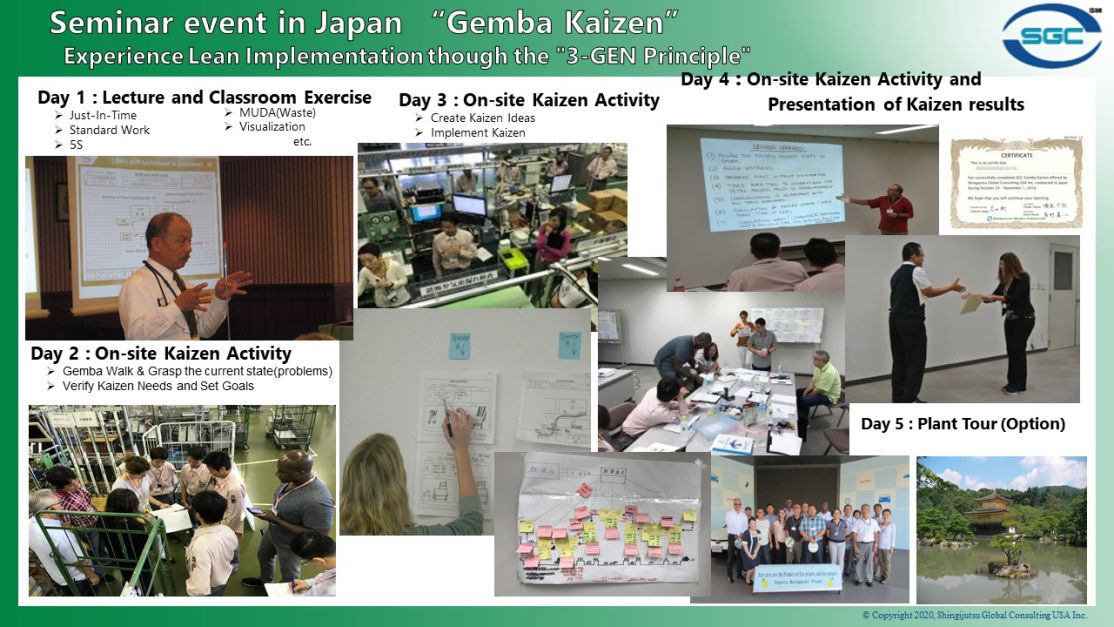

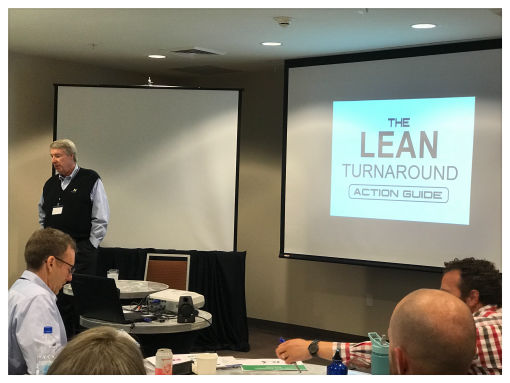

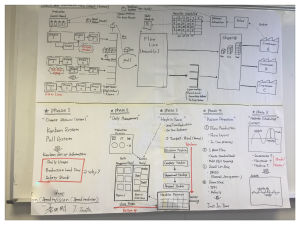

Public Seminars

SGC conducts regular public seminars, covering a variety of topics for every step of your Kaizen journey.

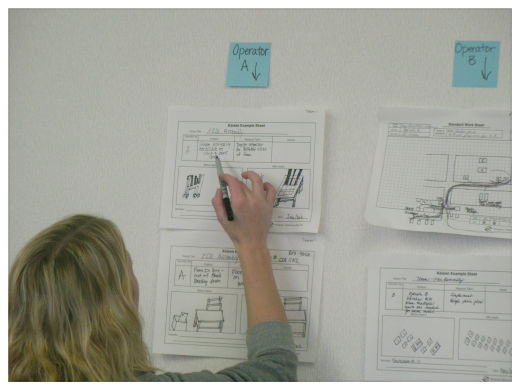

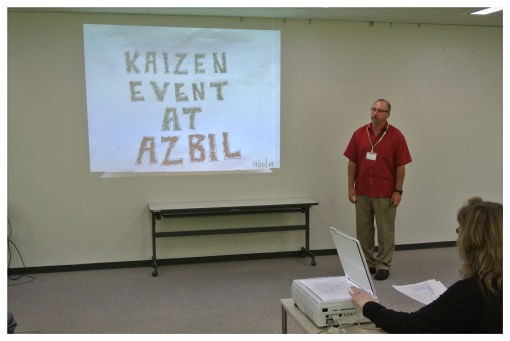

Private Seminars

SGC organizes an exclusive special seminar only for you. We propose a satisfactory seminar for each to meet the degree of lean advancement and study theme you are interested in. Please Contact us about your requests for private seminars.